Welder Shoes for Safety

Welding is a hazardous occupation that involves working with high temperatures, sparks, and heavy equipment, making safety a top priority. One of the most critical aspects of a welder’s personal protective equipment (PPE) is their footwear. Welder shoes, also known as welding boots or safety boots, are specifically designed to protect the feet from the dangers associated with welding. In this article, we will delve into the world of welder shoes, exploring their importance, key features, and the benefits they provide to welders.

Understanding the Risks

Welding involves a range of hazards, including electrical shock, slips, trips, and falls, and exposure to hot sparks and molten metal. These risks can lead to severe injuries, such as burns, lacerations, and even amputations. According to the Occupational Safety and Health Administration (OSHA), foot injuries are among the most common types of injuries in the welding industry. Therefore, it is essential to wear proper footwear that can withstand the demands of welding and provide adequate protection.

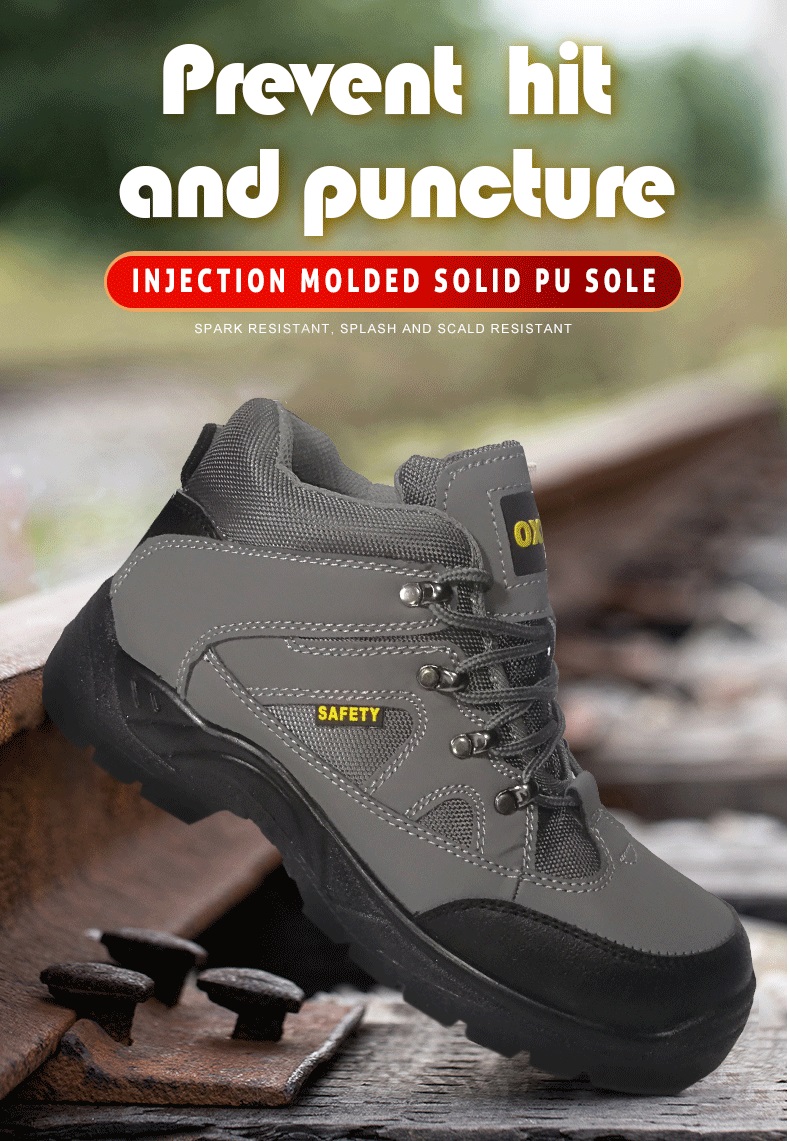

Key Features of Welder Shoes

Welder shoes are designed to provide superior protection and comfort for welders. Some of the key features of welder shoes include:

- Heat resistance: Welder shoes are made from materials that can withstand high temperatures, such as leather or heat-resistant synthetic materials.

- Insulation: Welder shoes often feature insulation to keep the feet warm in cold environments and cool in hot environments.

- Slip-resistance: Welder shoes have slip-resistant soles to prevent slips, trips, and falls on oily or wet surfaces.

- Electrical shock protection: Some welder shoes feature electrical shock protection, such as insulated soles and uppers, to prevent electrical shock.

- Ankle support: Welder shoes often have high ankle collars to provide support and prevent ankle injuries.

Types of Welder Shoes

There are several types of welder shoes available, each designed for specific welding applications. Some of the most common types of welder shoes include:

- Steel-toed boots: These boots feature a steel toe cap to protect the toes from heavy objects and equipment.

- Composite-toed boots: These boots feature a composite toe cap, made from materials such as plastic or carbon fiber, to provide a lighter and more comfortable alternative to steel-toed boots.

- Metatarsal boots: These boots feature a metatarsal guard to protect the metatarsal bones in the foot from injury.

- Welding sneakers: These shoes are designed for lighter welding applications and feature a more casual, sneaker-like design.

Benefits of Welder Shoes

Welder shoes provide a range of benefits to welders, including:

- Protection from injury: Welder shoes protect the feet from the hazards associated with welding, such as hot sparks and heavy equipment.

- Comfort: Welder shoes are designed to be comfortable and provide support for the feet during long welding sessions.

- Improved productivity: By providing a safe and comfortable working environment, welder shoes can improve productivity and reduce the risk of injury.

- Compliance with regulations: Welder shoes can help employers comply with OSHA regulations and industry standards for PPE.

Choosing the Right Welder Shoes

Choosing the right welder shoes can be a daunting task, with so many options available. When selecting welder shoes, consider the following factors:

- Type of welding: Different types of welding require different types of welder shoes. For example, shielded metal arc welding (SMAW) requires more protection than gas metal arc welding (GMAW).

- Work environment: The work environment, such as the temperature and surface type, can affect the choice of welder shoes.

- Personal preferences: Consider personal preferences, such as comfort and style, when selecting welder shoes.

Maintenance and Care

To extend the lifespan of welder shoes, it is essential to maintain and care for them properly. Some tips for maintaining and caring for welder shoes include:

- Cleaning: Regularly clean the shoes to remove dirt and debris.

- Conditioning: Condition the leather to keep it soft and supple.

- Storage: Store the shoes in a dry, cool place to prevent damage.

Conclusion

Welder shoes are a critical component of a welder’s PPE, providing protection from the hazards associated with welding. By understanding the importance of welder shoes, their key features, and the benefits they provide, welders can make informed decisions when selecting the right footwear for their needs. Whether you are a seasoned welder or just starting out, investing in a good pair of welder shoes can help prevent injuries and improve productivity.

What are the most common hazards associated with welding?

+The most common hazards associated with welding include electrical shock, slips, trips, and falls, and exposure to hot sparks and molten metal.

What are the key features of welder shoes?

+The key features of welder shoes include heat resistance, insulation, slip-resistance, electrical shock protection, and ankle support.

How do I choose the right welder shoes for my needs?

+When selecting welder shoes, consider the type of welding, work environment, and personal preferences. It is also essential to comply with OSHA regulations and industry standards for PPE.

How do I maintain and care for my welder shoes?

+To maintain and care for welder shoes, regularly clean them, condition the leather, and store them in a dry, cool place. This will help extend the lifespan of the shoes and ensure they remain effective.

What are the benefits of wearing welder shoes?

+The benefits of wearing welder shoes include protection from injury, comfort, improved productivity, and compliance with regulations. By wearing the right welder shoes, welders can ensure a safe and healthy working environment.