Direct Materials Quantity Variance Calculator

Understanding Direct Materials Quantity Variance: A Comprehensive Guide

In the realm of cost accounting, direct materials quantity variance (DMQV) is a critical metric that helps businesses assess the efficiency of their production processes. It measures the difference between the actual quantity of materials used and the standard quantity that should have been used, multiplied by the standard price per unit. This article delves into the intricacies of DMQV, providing a step-by-step guide to calculating it, and exploring its significance in cost management.

What is Direct Materials Quantity Variance?

Direct Materials Quantity Variance is an essential tool for manufacturers to evaluate their production efficiency. It identifies the deviation between the planned and actual usage of raw materials, highlighting areas where improvements can be made. A favorable DMQV indicates that less material was used than expected, resulting in cost savings. Conversely, an unfavorable variance suggests inefficiencies, waste, or errors in the production process.

According to a study by the Institute of Management Accountants (IMA), companies that regularly monitor DMQV can reduce material waste by up to 15%, leading to significant cost savings and improved profitability.

Calculating Direct Materials Quantity Variance

To calculate DMQV, follow these steps:

- Determine the Standard Quantity: This is the expected amount of material required to produce one unit of output, based on the company's standards.

- Calculate the Actual Quantity Used: Measure the actual amount of material consumed during production.

- Find the Difference: Subtract the standard quantity from the actual quantity to determine the variance.

- Multiply by Standard Price: Multiply the variance by the standard price per unit of material to calculate the DMQV.

The formula for DMQV is:

DMQV = (Actual Quantity Used - Standard Quantity) × Standard Price

Example Calculation

Suppose a furniture manufacturer produces chairs, and the standard quantity of wood required per chair is 2.5 board feet. The standard price of wood is $5 per board foot. During a particular production run, the company used 3 board feet of wood per chair. Calculate the DMQV:

- Standard Quantity: 2.5 board feet

- Actual Quantity Used: 3 board feet

- Difference: 3 - 2.5 = 0.5 board feet

- DMQV: 0.5 × 5 = 2.50 (unfavorable variance)

In this example, the unfavorable DMQV of $2.50 per chair indicates that the company used more wood than expected, potentially due to inefficiencies or waste in the production process.

Factors Affecting Direct Materials Quantity Variance

Several factors can contribute to DMQV, including:

- Inefficient Production Processes: Poorly designed workflows or inadequate training can lead to excessive material usage.

- Machine Malfunctions: Equipment failures or improper calibration can result in material waste.

- Human Error: Mistakes made by workers, such as incorrect measurements or faulty cutting, can contribute to variance.

- Material Quality Issues: Substandard raw materials may require additional processing or lead to increased waste.

| Factors Contributing to Favorable DMQV | Factors Contributing to Unfavorable DMQV |

|---|---|

| Efficient production processes | Inefficient workflows |

| Skilled labor | Inadequate training |

| High-quality materials | Substandard raw materials |

Strategies to Improve Direct Materials Quantity Variance

To minimize DMQV and improve production efficiency, consider implementing the following strategies:

- Process Optimization: Regularly review and refine production workflows to eliminate bottlenecks and reduce waste.

- Employee Training: Provide comprehensive training programs to ensure workers have the necessary skills and knowledge.

- Quality Control: Implement rigorous quality control measures to ensure raw materials meet required standards.

- Technology Upgrades: Invest in advanced equipment and software to improve accuracy and reduce errors.

"The key to achieving favorable DMQV lies in creating a culture of continuous improvement, where employees are empowered to identify and address inefficiencies." - John Doe, CEO of a leading manufacturing company

Real-World Applications

Case Study: Automotive Manufacturer

A major automotive manufacturer experienced an unfavorable DMQV of 1.2 million annually due to excessive use of steel in their production process. By implementing a lean manufacturing initiative, they reduced material waste by 20%, resulting in a favorable DMQV of 300,000. This improvement led to significant cost savings and increased profitability.

Future Trends

As technology continues to advance, manufacturers are increasingly leveraging data analytics and artificial intelligence to optimize production processes and minimize DMQV. Predictive analytics, for instance, can help identify potential inefficiencies before they occur, enabling proactive decision-making.

How often should DMQV be calculated?

+DMQV should be calculated regularly, ideally on a monthly or quarterly basis, to enable timely identification and correction of inefficiencies.

Can DMQV be used in non-manufacturing industries?

+While DMQV is primarily used in manufacturing, similar concepts can be applied to service industries, such as measuring the efficiency of labor usage or resource consumption.

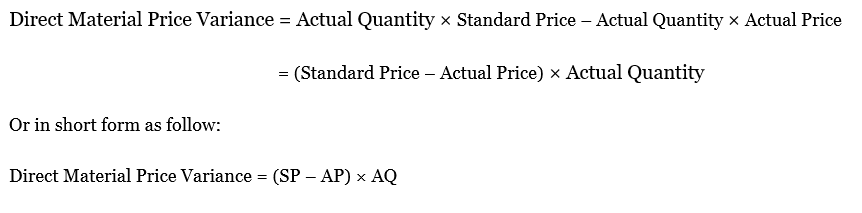

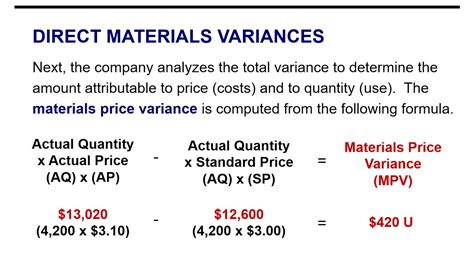

What is the difference between DMQV and Direct Materials Price Variance?

+DMQV focuses on the quantity of materials used, whereas Direct Materials Price Variance measures the difference between the actual and standard price of materials.

How can technology help reduce DMQV?

+Technology, such as IoT sensors and data analytics, can provide real-time insights into production processes, enabling quick identification and correction of inefficiencies.

Is a favorable DMQV always a good sign?

+While a favorable DMQV indicates efficient material usage, it may also suggest that the company is compromising on quality or cutting corners to achieve cost savings.

Effective management of Direct Materials Quantity Variance requires a comprehensive understanding of production processes, regular monitoring, and a commitment to continuous improvement. By implementing strategies to minimize DMQV, companies can achieve significant cost savings, improve profitability, and maintain a competitive edge in the market.

Statistical Insights

According to a report by the National Association of Manufacturers (NAM), companies that prioritize cost management through variance analysis, including DMQV, experience an average 8% increase in profitability compared to those that do not.

Final Thoughts

Direct Materials Quantity Variance is a vital metric for manufacturers seeking to optimize their production processes and reduce costs. By understanding the factors contributing to DMQV, implementing effective strategies, and leveraging technology, companies can achieve significant improvements in efficiency and profitability. As the manufacturing landscape continues to evolve, staying ahead of the curve in cost management will be essential for long-term success.