Best Non Slip Work Boots

Maintaining traction and preventing slips, trips, and falls is crucial in various work environments, especially in industries such as construction, manufacturing, and healthcare. Non-slip work boots are designed to provide the necessary grip on different surfaces, ensuring worker safety and preventing potential accidents. When selecting the best non-slip work boots, several factors must be considered, including the type of workplace, the nature of the job, and personal comfort preferences.

Importance of Non-Slip Work Boots

Non-slip work boots are not just a precautionary measure but a necessity in many workplaces. They are designed with specialized outsoles that provide superior traction on various surfaces, including oily, wet, and slippery floors. The primary goal of these boots is to reduce the risk of slips, trips, and falls, which are among the most common types of workplace injuries. By wearing non-slip work boots, workers can significantly lower their risk of experiencing such accidents, ensuring a safer and healthier work environment.

Features to Look for in Non-Slip Work Boots

Traction and Grip: The outsole of the boot is the most critical feature when it comes to non-slip performance. Look for boots with aggressive tread patterns and deep lugs that can provide excellent grip on different surfaces.

Material: The material of the outsole is also crucial. Rubber compounds that are resistant to oil and slippery substances are ideal. Some boots also feature special materials that enhance grip on specific surfaces.

Comfort: While safety is paramount, comfort should not be compromised. Non-slip work boots should be comfortable to wear for extended periods, featuring breathable materials, cushioning, and a comfortable fit.

Durability: The boots should be durable enough to withstand the demands of the workplace. This includes resistance to wear and tear, as well as protection from hazards such as sharp objects and heavy impacts.

Certifications: Look for boots that meet or exceed safety standards set by reputable organizations. Certifications can indicate that the boots have been tested for slip resistance and other safety parameters.

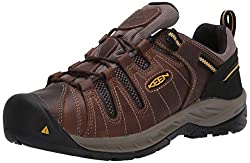

Top Picks for Non-Slip Work Boots

Given the variety of workplaces and job requirements, the best non-slip work boots can vary significantly. Here are some top picks across different categories:

- For General Industry: The Dr. Martens Ironbridge is a popular choice, offering excellent slip resistance along with comfort and durability.

- For Construction and Heavy Industry: The Thorogood American Heritage series is highly regarded for its superior traction, comfort, and protection against workplace hazards.

- For Healthcare and Service Industry: The Dansko XP 2.0 is favored for its slip-resistant outsole, comfort, and ease of cleaning, making it ideal for environments where hygiene is paramount.

- For Outdoor and Slippery Conditions: The Bogs Classic Ultra High is admired for its exceptional grip in wet and muddy conditions, along with its waterproof design and comfort features.

Maintenance and Care

To ensure that non-slip work boots perform optimally, regular maintenance is essential. This includes cleaning the outsoles regularly to remove dirt and debris that can compromise traction, checking the boots for wear and tear, and storing them in a dry place when not in use. Proper care can extend the life of the boots and maintain their non-slip functionality.

Conclusion

Selecting the best non-slip work boots requires a thorough understanding of the workplace environment, the specific demands of the job, and the features that contribute to slip resistance and overall safety. By prioritizing traction, comfort, durability, and certifications, workers can find boots that not only meet but exceed their safety and performance needs. Remember, safety is a shared responsibility, and wearing appropriate non-slip work boots is a critical step in preventing accidents and ensuring a safe working environment.

What makes a work boot truly non-slip?

+A truly non-slip work boot features an outsole made from a material with a high coefficient of friction, such as specialized rubber compounds, and is designed with a tread pattern that maximizes contact with the ground, providing superior grip on various surfaces.

How often should non-slip work boots be replaced?

+The lifespan of non-slip work boots depends on usage, but generally, they should be replaced when the outsole shows significant wear, the tread is worn down, or when the boots no longer provide the necessary comfort and support. This can range from a few months to several years.

Can non-slip work boots be used in all types of workplaces?

+While non-slip work boots are essential in workplaces with slippery conditions, the specific type of boot needed can vary significantly depending on the work environment. For example, construction sites may require boots with additional features such as steel toes and puncture resistance, whereas healthcare settings may prioritize ease of cleaning and hygiene.